Top Quality Brake Pads Brands: Why ADUI Brake Pads are Your Trusted Choice for Performance

Ensuring Brake Pad Quality and Performance: ADUI's Investment in Innovation and Rigorous Testing

Top Quality Brake Pads Brands: Why ADUI Brake Pads are Your Trusted Choice for Performance

When it comes to brake pads, quality is key. Poor quality brake pads can lead to reduced performance, noise issues, and even safety risks. That's why it's essential to choose high-quality brake pads from reputable brands.

At ADUI, we are committed to providing our customers with the best possible brake pads on the market. We understand the importance of quality and have invested heavily in our production line, quality inspection, and performance testing equipment. Our German Intermittent hybrid mixers, fully automatic weighing scales, and optical comparators are just a few examples of the cutting-edge technology we use to produce our brake pads.

Our research and development team is continually working to improve the friction material used in our brake pads. Our goal is to increase braking performance and longevity while reducing noise and dust. We conduct extensive testing to ensure our products are safe for the braking system and meet industry standards.

Ensuring Brake Pad Quality and Performance: ADUI's Investment in Innovation and Rigorous Testing

At ADUI, we take a "quality first" approach to everything we do. We believe that product consistency and stability are essential to providing our customers with the best possible experience. That's why we subject our brake pads to rigorous market testing in Taiwan and strive to exceed our customers' expectations.

When you choose ADUI brake pads, you can be confident that you're getting a high-quality product from a trusted brand. Our brake pads are designed to provide superior performance, safety, and longevity. So, whether you're a professional mechanic or a DIY enthusiast, you can trust ADUI brake pads to get the job done right.

ISO Recognition

ADUI applies various management systems. All our products are manufactured based on ISO 9001 regulations and are tested with precise inspection equipment and testing instruments for product development and verification.

NT$10 million Product Liability Insurance

Our product is underwritten by Tokio Marine Products Insurance Company with a product liability insurance of NT$10 million, which take effect within the scope of use in compliance with safety regulation

(Taiwan Only)

High Specifications, High Standards, Professionalism

Quality Control

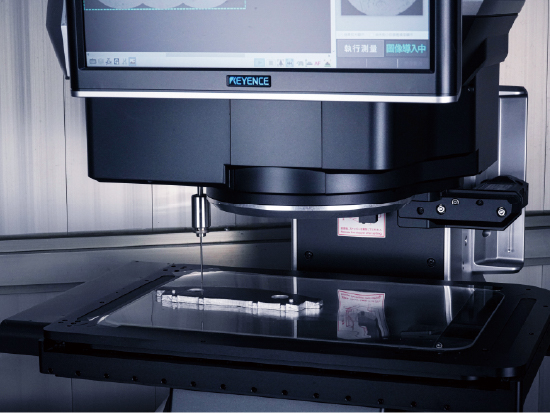

Optical Comparator

Ensure that the measurements of raw materials meet our inspection standards.

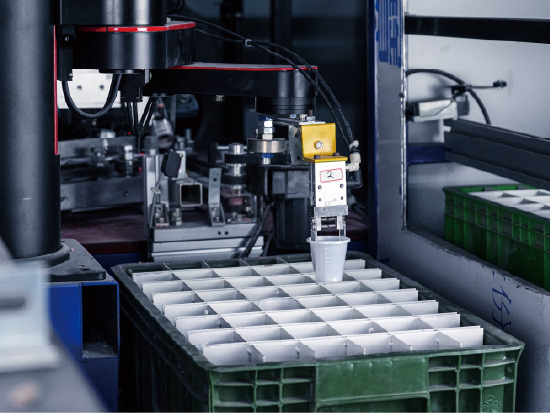

Fully Automatic Weighing Scales

Precisely mix raw material according to proportion. Automation increases production.

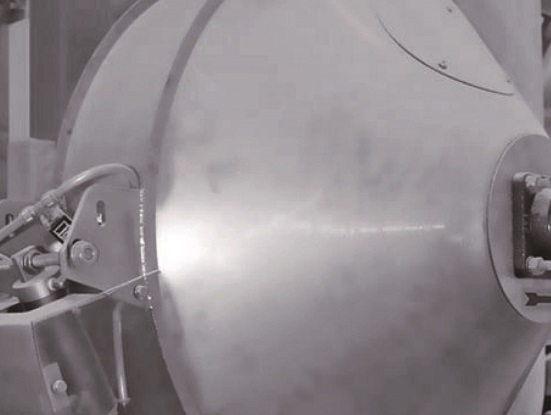

German Intermittent Hybrid Mixers

Speedy mixing speed, materials are evenly mixed.

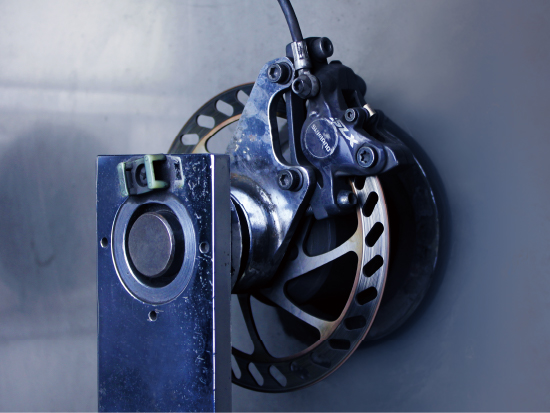

Bicycle Dynamic Simulation Testing Machine

Periodical test takes place to ensures quality and stability of mass-produced brake pads for bicycles.

NT15 Inertia Dynamic Simulator Testing Machine

Periodical test takes place to ensure the quality and stability of mass-produced brake pads for automobiles and motorcycles.

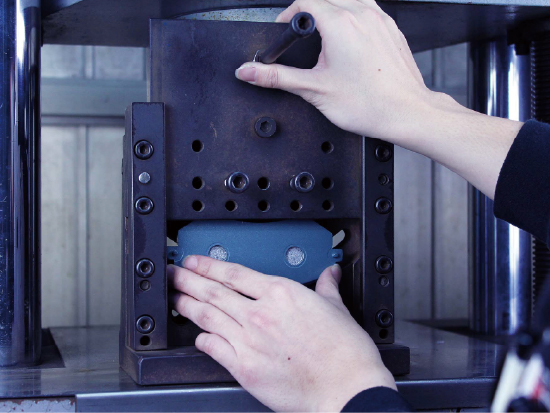

Universal Testing Machine

To test the strength of the bond between the friction material and back plate.

Rockwell Hardness Testing Machine

Test the hardness of brake pads meets the requirements of physical properties.

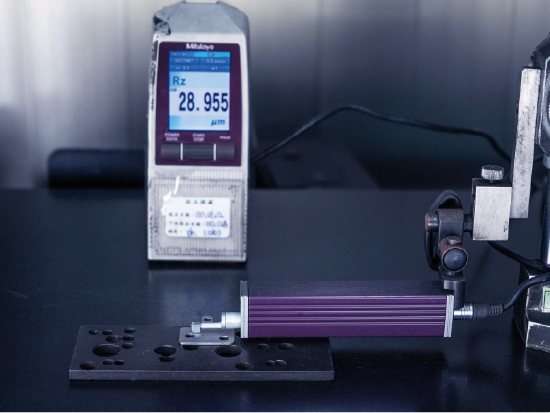

Surface Roughness Comparator

Periodical test takes place to check the roughness of the back plate and adhesion of the adhesive and paint.

Salt Spray Testing Machine

To test rust-proof ability that had been through surface treatment and improves paint rust-proof ability.

Environmental Compliances

Material regulations

Non-Asbestos, REACH, ROSH 2.0